DTF (Direct to Film) printing technology has revolutionized the textile industry by offering high-speed, high-efficiency production compared to traditional methods like screen printing or heat transfer. However, understanding the balance between speed and resolution is crucial for maximizing performance and quality.

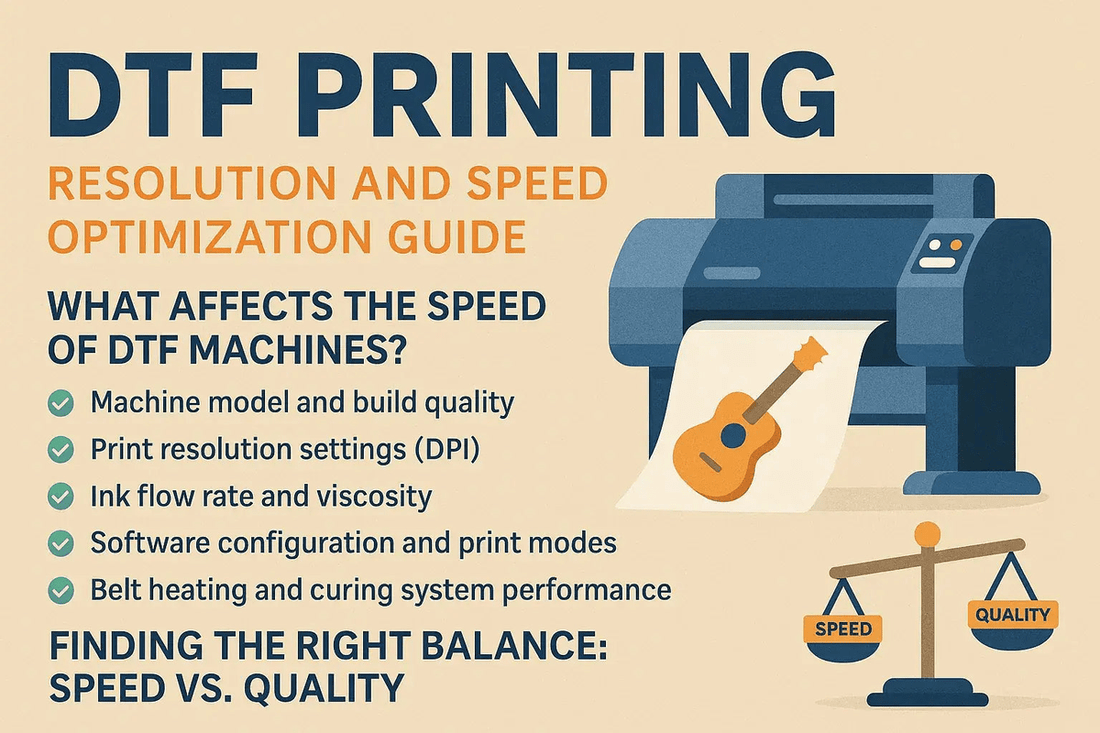

What Affects the Speed of DTF Machines?

Several factors directly influence the production speed of DTF printers. If these variables are not optimized, machines may slow down over time, affecting overall output.

Key factors include:

- ✅ Machine model and build quality

- ✅ Print resolution settings (DPI)

- ✅ Ink flow rate and viscosity

- ✅ Software configuration and print modes

- ✅ Belt heating and curing system performance

⚠️ Important: Increased speed can sometimes lead to decreased print quality—especially if low-grade inks, films, or worn print heads are used.

Some advanced DTF machines offer up to 25% faster performance than standard models while maintaining comparable quality, making them ideal for high-volume, fast-turnaround operations.

DPI in DTF Printing: Why It Matters

One of the most critical elements in achieving high-quality DTF prints is the DPI (Dots Per Inch) setting. DPI defines how many ink dots the printer places within a one-inch line. The higher the DPI, the sharper and more detailed the image appears.

Key factors influencing DPI and resolution quality:

- 🔹 Print head type and condition

- 🔹 Ink formulation and pigmentation

- 🔹 DTF film coating quality

- 🔹 Software precision and color profiling

- 🔹 Print speed (spray timing & control)

For businesses focused on vibrant, photorealistic prints, high DPI is non-negotiable. On the other hand, for industries prioritizing speed (e.g. workwear or promotional merchandise), a medium DPI may be sufficient.

Finding the Right Balance: Speed vs. Quality

Every print shop must strike a balance based on their priorities:

- If you're printing personalized garments or art-quality designs, opt for higher resolution settings with slightly reduced speed.

- For bulk production or same-day delivery needs, choose machines that support fast printing with minimal quality loss.

By using high-performance DTF machines and adjusting your DPI settings strategically, you can satisfy both operational efficiency and customer satisfaction.

Final Thoughts

Speed and resolution are the twin pillars of successful DTF printing. By understanding how these two factors interact, print businesses can deliver both quality and quantity—without compromise.

👉 Ready to upgrade your DTF workflow?

Visit DTFPrinterUSA.com to explore industry-leading DTF printers, inks, and accessories engineered for speed and precision.