DTF Printer Film Rolls & Sheets

-

A3 DTF Paper (100 Sheets)

- $44.99

$53.99- $44.99

- Unit price

- / per

Save $9.00 -

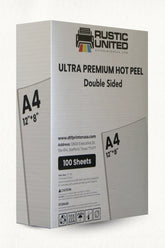

A4 DTF Paper (100 Sheets)

- $24.99

$29.99- $24.99

- Unit price

- / per

Save $5.00 -

Ultra Premium Hot Peel (24"x328 Feet)

Ultra Premium Hot Peel 24" - High-Quality DTF Film Transform your t-shirt printing with our Ultra Premium Hot Peel 24" DTF Film—the perfect solution for achieving vibrant, durable designs on both light and dark fabrics. Designed with ease and efficiency in mind, this hot...- $63.95

$104.95- $63.95

- Unit price

- / per

Save $41.00 -

Premium Double Matte Hot Peel (24"x328 Feet)

Premium Double Matte Hot Peel Introducing our exceptional DTF double matte hot peel film, designed to cater to all materials with unparalleled quality. Its user-friendly nature guarantees effortless printing while delivering long-lasting, high-quality prints. With our satisfaction guarantee, you can purchase with complete confidence,...- $62.95

$99.95- $62.95

- Unit price

- / per

Save $37.00 -

Premium Single Matte Hot Peel (24"x328 Feet)

Premium Single Matte Hot Peel Discover our high-quality DTF hot peel film, ideal for various materials. Our one-sided Single Matte film excels in printing on light and dark fabrics, offering ease of use for beginners. Crafted from premium materials and backed by our satisfaction...- $61.95

$97.95- $61.95

- Unit price

- / per

Save $36.00 -

Double Matte Smart Peel (24"x328 Feet)

SMART PEEL DOUBLE MATTE Looking for high-quality DTF Double Matte Smart Peel film for your t-shirts? Look no further than our two-sided film. Perfect for printing on both light and dark fabrics, this film can be peeled off whether it's cold or hot, making...- $61.95

$94.95- $61.95

- Unit price

- / per

Save $33.00 -

Single Matte Smart Peel (24"x328 Feet)

SMART PEEL Single MATTE Looking for high-quality DTF Single Matte Smart Peel film for your t-shirts? Look no further than our one-sided film. Perfect for printing on both light and dark fabrics, this film can be peeled off whether it's cold or hot, making...- $61.95

$94.95- $61.95

- Unit price

- / per

Save $33.00 -

Ultra Premium Hot Peel (16"x328 Feet)

Ultra Premium Hot Peel 16" - High-Quality DTF Film Transform your t-shirt printing with our Ultra Premium Hot Peel 16" DTF Film—the perfect solution for achieving vibrant, durable designs on both light and dark fabrics. Designed with ease and efficiency in mind, this hot...- $49.95

$84.95- $49.95

- Unit price

- / per

Save $35.00 -

Double Matte Smart Peel (12"x328 Feet)

Double Matte Smart Peel Looking for high-quality DTF Double Matte Smart Peel film for your t-shirts? Look no further than our two-sided film. Perfect for printing on both light and dark fabrics, this film can be peeled off whether it's cold or hot, making...- $44.95

$69.95- $44.95

- Unit price

- / per

Save $25.00 -

UV DTF Film A/B 24 inch

Introducing UV DTF Film A, the premier choice for achieving stunning, high-quality prints on your apparel. Specially formulated to deliver vibrant, long-lasting graphics with a smooth, glossy finish, UV DTF Film A is designed to work flawlessly on both light and dark fabrics, offering...- $224.95

$274.95- $224.95

- Unit price

- / per

Save $50.00 -

UV DTF Film A/B 12 Inch

Introducing UV DTF Film A, the premier choice for achieving stunning, high-quality prints on your apparel. Specially formulated to deliver vibrant, long-lasting graphics with a smooth, glossy finish, UV DTF Film A is designed to work flawlessly on both light and dark fabrics, offering...- $112.95

$162.95- $112.95

- Unit price

- / per

Save $50.00 -

DTF Direct to Film 24" x 328ft | Glitter Film for High-Quality Transfers

Burak added this description- $259.95

$94.95- $259.95

- Unit price

- / per

Save $-165.00

High-Performance DTF Film Rolls & Sheets for Professional Transfers

Whether you’re printing for a small shop or managing large production runs, our DTF film delivers clean transfers, sharp color, and smooth peel performance every time. Engineered for professional results, each roll and sheet ensures excellent ink absorption and vibrant color output on cotton, polyester, blends, and more. Trusted by print shops nationwide, DTF Printer USA is your reliable DTF film supplier for consistent results and fast delivery.

Shop DTF Film by Type

We stock a full range of DTF transfer film options to fit your setup. Whether you need hot peel, cold peel, or UV DTF film, each type is designed to optimize your workflow and reduce waste. Our best-selling rolls include:

-

Premium Single Matte Film – 24” x 328 ft

-

Double Matte Smart Peel – 24” x 328 ft

-

Double Matte Cold Peel – 24” x 328 ft

-

Ultra Premium DTF hot peel film – 16”

-

UV DTF A/B Film Set – 12” or 24”

All films are anti-static, smudge-resistant, and compatible with most commercial DTF printers and dryers. Whether you’re ordering a roll or testing smaller DTF film sheets, you’ll get uniform coating and flawless transfer quality.

Film Rolls vs Sheets

Choosing between DTF film rolls and sheets depends on your production volume. Rolls are ideal for high-output businesses that value continuous printing and reduced handling time. Sheets work best for small-batch runs, sample designs, or one-off custom projects. Both formats provide the same professional-grade adhesion and release properties for crisp, clean edges and long-lasting prints.

UV DTF Film Collection

For designers and brands expanding into non-fabric surfaces, our UV DTF A/B film sets are a game changer. These dual-layer films allow transfers onto glass, metal, wood, and plastic with stunning clarity and adhesion. With competitive UV DTF film price options and tested formulations, they’re perfect if you’re looking for the best DTF film near you with top performance and reliability.

Complete Your Workflow

Pair your film rolls with our premium DTF supplies, including inks, transfer powders, and heat presses, for a fully optimized production setup. Every component is designed to work seamlessly together for professional, repeatable results that keep your business running smoothly.